Stronga: de biomasa a energía

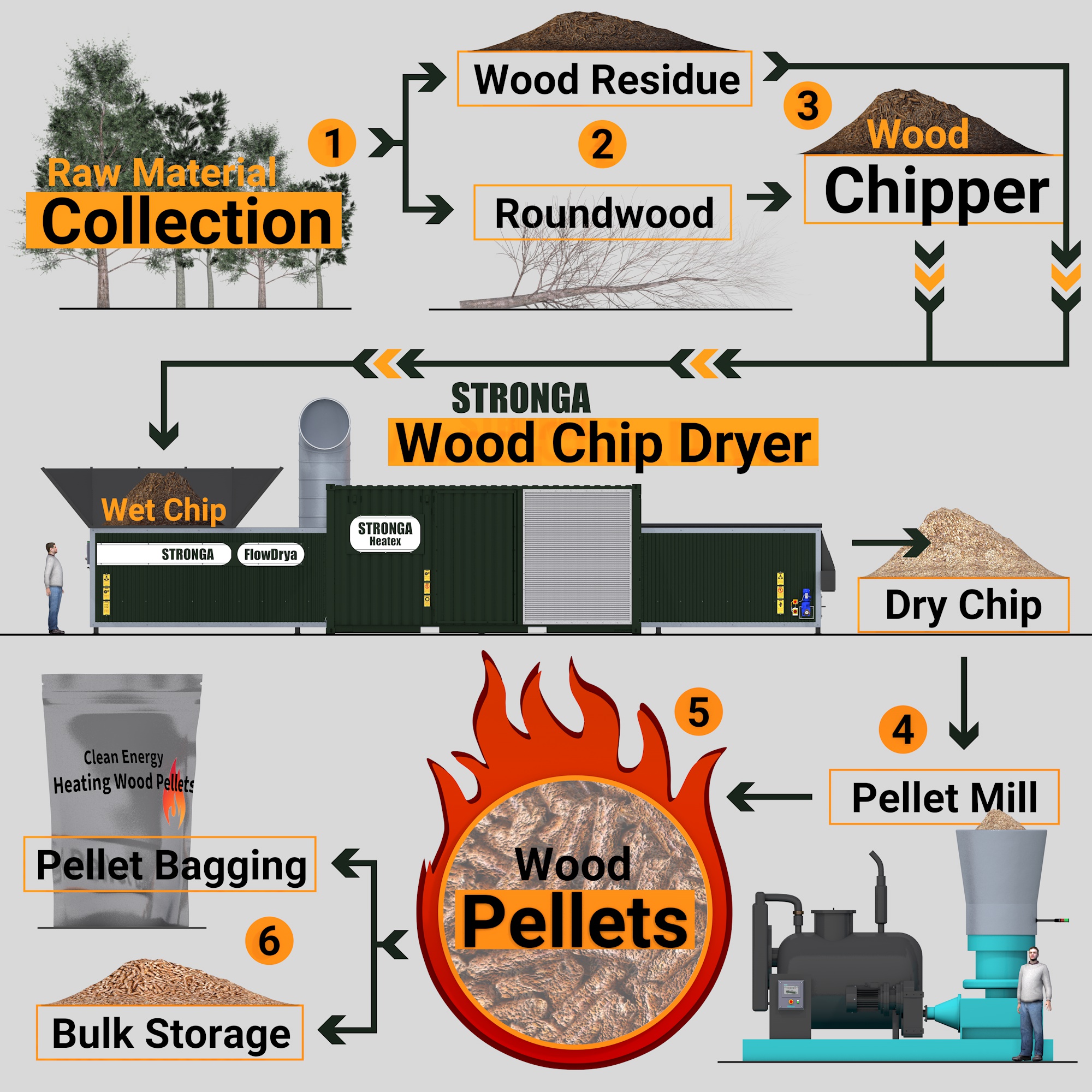

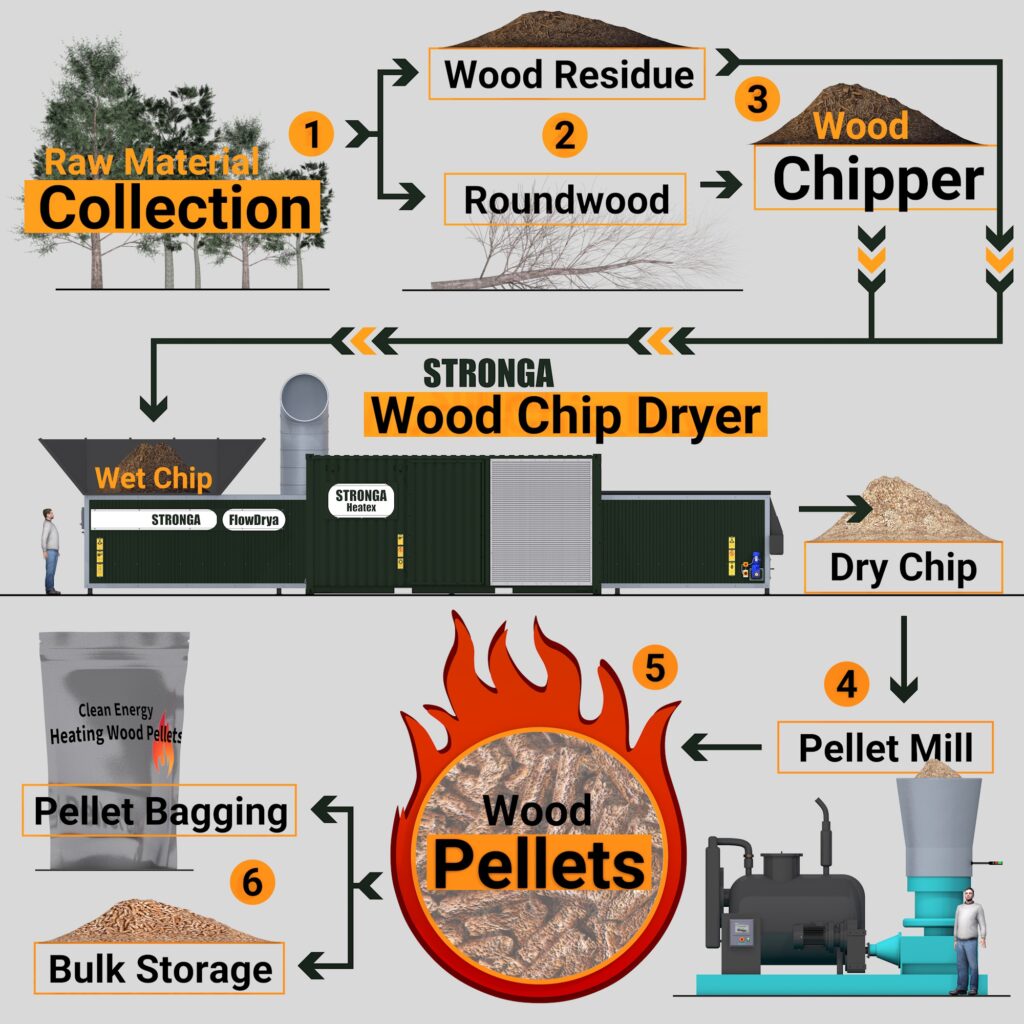

| Pellet Power – The Biomass Market Compared to fossil fuels which have increased in price significantly of late, woody biomass has proven more stable. Pellets can be used for cogeneration, CHP and domestic energy requirements, providing a more renewable supply of alternative energy. Wood pellets can also be easily stored and transported, while biomass CHP will often qualify for heat and electricity subsidies. Forecasts estimate global demand for industrial wood pellets is set to reach 36 million tonnes by 2027, meaning that demand would have increased by over 50% since 2017. Forestry owners and sawmills are among those that have sensed a unique opportunity to use residues to sell wood fuel pellets while demand is increasing. Learn below about Stronga’s work with an eco-conscious wood pellet producer in Australia. |

| Collaboration with Sustainable Wood Pellet Producer Stronga recently collaborated with a pelleting company who have succeeded in producing CO₂-neutral pellets from sawdust residue. They have adopted a fair approach to sustainability through producing low moisture wood pellets with high combustion efficiency and no chemical binders, striking a balance between high energy demands and reduced fossil fuel usage. By sourcing residual wood for pellet production, their sustainability prospect aligned with Stronga’s philosophy of transforming waste into added value. |

| Drying at the Centre of Pellet Production Drying biomass is an essential step in profitable pellet production; not only does it limit VOC emissions and micro-pollutants; it also significantly increases the pellets energy output. Stronga has engineered the FlowDrya to help clients minimise energy consumption and optimise drying efficiency, providing a more effective and greener dryer for more sustainable pellet production. Increasingly, stringent wood pellet standards are being developed; the choice of a suitable dryer is a critical decision when accounting for the overall energy demands of the process. Learn more about the project online > |

| A Masterpiece in Moisture Removal In this case, where the client already had an existing but in-efficient rotary drum dryer, Stronga scaled the FlowDrya for use in-front of the process, commissioning a heat exchanger to productively utilise the residual on-site exhaust air. If you have access to residual material which can be transformed into profit, talk to Stronga and begin a collaborative journey towards more sustainable and productive operations – info@stronga.co.uk |